Wholesales Round Indented Hexagon Washer/Flange Screw

Basic Info

| Model NO. | 4*12 |

| Connection | Common Bolt |

| Head Style | Hexagonal |

| Standard | DIN, GB, ANSI, BSW, JIS, GOST |

| Grade | 4.8 |

| Shipping Cost | to Be Negotiated |

| Customization | Available |

| Samples | to Be Negotiated |

| Delivery Time | 15-30 Days |

| Head Type | Phillips /Slotted /Hex /Round /Torx |

| Certification | ISO9001, SGS |

| Surface Treatment | Customize |

| Class/Gread | 3.6,4.8,5.6,6.8,8.8,9.8,10.9,12.9 |

| Transport Package | Plastic Bag/Boxs /Cartons/Pallets/Customize |

| Specification | 4*12 |

| Trademark | LIHAO Hardware |

| Origin | China |

Packaging & Delivery

Package size per unit product 23.00cm * 19.00cm * 23.00cm Gross weight per unit product 25.000kgProduct Description

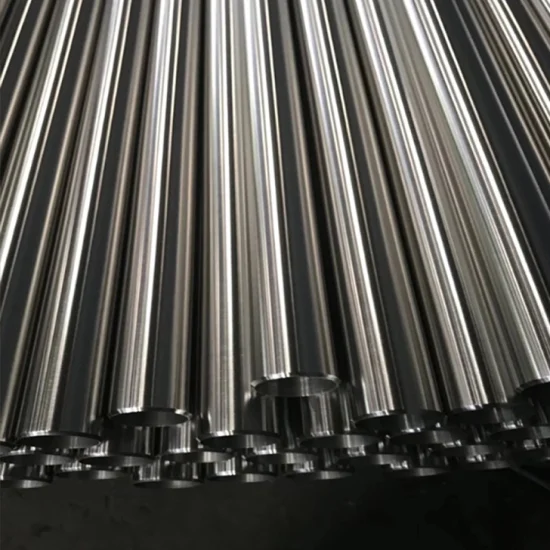

Wholesales Round Indented Hexagon Washer/Flange ScrewProduct Description

| Item | Wholesales Round Indented Hexagon Washer/Flange Screw |

| Head Type | Indented Hexagon Washer/Flange Head |

| Drive Style | Round |

| Material | Stainless Steel |

| Finish | NIL |

| Available Raw Material | Carbon steel |

| Alloy steel | |

| Stainless steel | |

| Brass, Bronze, Aluminum | |

| Standard | DIN,ANSI,ASTM,JIS,GB,ISO,NON-STANDARD |

| Grade | 3.6/4.8/5.6 /6.8/8.8/9.8/10.9/12.9 |

| Surface finishing | PlainGalvanized (various of color) ,Zinc-Plated (various of color)Nickel- Plated, Chrome-Plated, Oxide BlackPassivation, Dacromet, Nylok Precote,Baking Paint/Stoving Varnish,Electrophoresis Black |

| Heat Treatment | Carburization or tempering or high-frequency quenching |

| Packing | Plastic Bag/Boxes /Cartons/Pallets/Customize, or customer request |

"Excellent quality, good service system" is the guarantee of success, is the real commitment and return to customers! We take "quality, service, innovation, development" as the eternal theme of the business philosophy, and the company will continue to improve the production process, improve the service system, in accordance with the industry quality standards, welcome to call the consultation.

Our workshopOur servicesCooperative brandPackaging & ShippingFAQ

1.Are you trading company or manufacturer?

We are factory with 20+ years experience in fastener making in China. 2.Do you provide samples? Is it free or fee charge?

Free samples will be ready within 3 days if available in stock or if tooling is available, but we do not pay for shipping.If we don't have any in stock, we need to re-customize the sample and charge the sample fee.3. What is your delivery time?

It depends on if we have stock or not, if we have stock goods, we can delivery within 3-5 days after receive the payment. And normally our production is in 20-30 days for products.

4.Can you give me help if my products are very urgent?Yes, we will try our best give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule. 5.I want to keep our design in secret, can we sign NDA?Sure, we will not display any customers' design or show to other people, we can sign NDA. 6.Can we know the production process without visiting the factory?We will offer detailed production schedule and send pictures and videos which show the machining progress.