Plastic Beams for Construction Galvanized Scaffolding Frame for Construction Waterproof Formwork Plywood

Basic Info

| Model NO. | plastic beams for construction |

| After-sales Service | Online Technical Support |

| Certification | ISO |

| Material | Polypropylene |

| Type | Slab Formwork |

| Thickness | 12-21mm |

| Application | Concrete Construction |

| Advantage | Reusable,Waterproof |

| Color | Grey White, White & Black ,Black |

| Transport Package | Paperboard on Pallet |

| Specification | 1220*2440/1250*2500mm |

| HS Code | 392690000 |

| Production Capacity | 1000PCS/Day |

Product Description

The pp hollow plastic construction formwork produced by BEIZHU uses imported polypropylene resin as basic material, adding chemical additives toughening, flame resistance, weather resistance and anti-aging, smelt and form new construction material through chemical molecular structure reorganization.

Standard Size | Container Loading (pcs) | Weight (kg/pc) | |

(mm) | 20ft | 40HQ | |

1220*2440*12 | 560 | 1120 | 20-21 |

1220*2440*15 | 432 | 1026 | 24-25 |

1220*2440*18 | 400 | 900 | 27-28 |

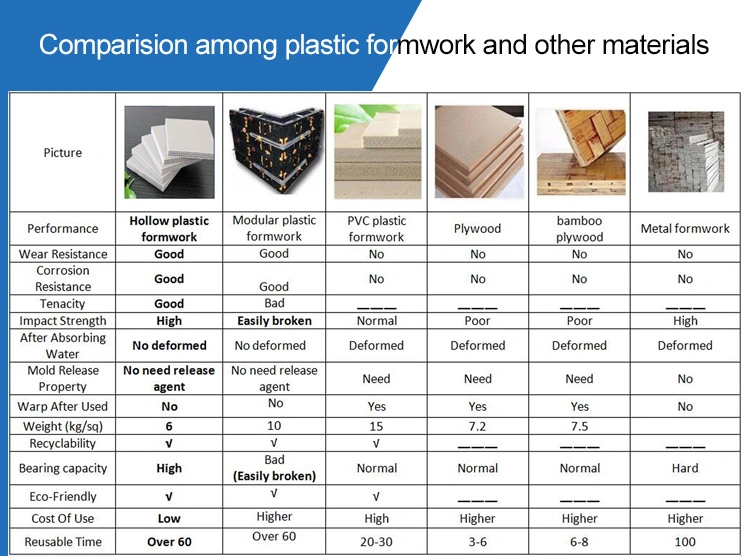

Product DescriptionThe plastic concrete formwork produced by Sufeng uses polypropylene as basic material, adding chemicaladditives toughening, flame resistance, weather resistance and anti-aging, smelt and form new constructionmaterial through chemical molecular structure reorganization.

Hollow plastic formwork is according to the principle of structural mechanics, neatly arranged, increasedfour times support, stronger and more robust;On both sides of the formwork are right angle processing,increasing the bear capacity, construction is more convenient.

Hollow formwork principle also makes the product expansion coefficient small.

| STANDARD SIZE | Quantity in 20ft Container | Quantity in 40hq Container | Weight |

| 2440*1220*12MM | 560 PCS | 1260 PCS | 21 KGS/PC |

| 2440*1220*15MM | 450 PCS | 1120 PCS | 24 KGS/PC |

| 2440*1220*18MM | 400 PCS | 900 PCS | 28 KGS/PC |

| 2440*1220*20MM | 350 PCS | 850 PCS | 30 KGS/PC |

Remark:

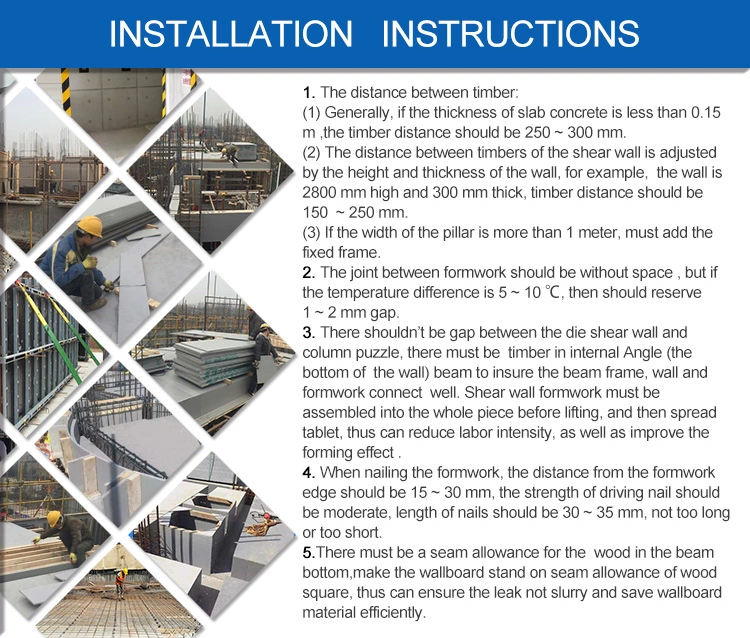

1) Please use tungsten steel saw blade with over 80 meshes when you cutting the plastic formwork.

2) Please avoid the peak temperature in one day when matching the mold. Then the effect after releasingmould is better.

3) Please place the PP formwork as flat as plywood formwork prevent the deformation after releasing the mould.

4) Please have your building workers skill trained when you use PP formwork first time. This is an essential part.General Operation And Notes Of Instrument For Beizhu concrete formwork :1. Method of use as well as wooden formwork, Beizhu concrete formwork reinforcement direction with battendirection placed in cross shaped.2. No need to smear the mold release agent before using Beizhu concrete formwork.3. When cast-in-place the flat plate, spacing between the keels should be 20 ~ 25 cm, and the spacing betweenthe wall plate and keels hould be 10 ~ 20 cm. BEIZHU Beizhu concrete formwork don't need releasing agent.4. The seam-line between Beizhuconcrete formwork should be taped.5. The length of nail should not be too long, generally about 30 ~ 35 mm.6. The strength to drive nailsshould be moderate.7. When removing the Beizhu concrete formwork, please start from the small part of one end, the support andthe plates should be removed at the same time aiming at preventing the template widespread drops, don't letthe corner drop on the ground vertically.8. The Sufeng concrete formwork accesses to be mixed used with wood veneer, bamboo veneer and othermaterial plate.

Company ProfileShanxi SUFENG New Material Technology produced plastic concrete formwork since 2008 andexported since 2005. We have past the certificate of ISO9001:2008 International Quality System in 2015;The plastic concrete formwork has been accepted and applied in construction in China, India, Australia,Singapore, UAE, Finland, Mexico and other countries. We have got the positive feedback from ourcustomers. This new construction material will be popular and used widely all over the world.

FAQQ: Are you a factory or trading company?

A: Factory

Q: How can I get the sample?

A:We provide sample free of charge 3-7 work days

Q: What payment terms do you do?

A: 30% T/T as down payment, the balance paid by T/T before shipmentor 100% irrevocable L/C At sight

Q: What is your MOQ for Beizhu concrete formwork?

A: We have some stock for normal size, so it depends on your requirement

Q: How long is your delivery time?

A: 10-15 work days

Q: How to pack the product?

A: On pallet and carton or as customers' requirement

Q: How many quantity can load for one 20/40 container?

A: For 18mm thickness, 400PC/20GP container, 900PC/40HQ container.